GOAL

Our client came to us for a mould design which could be imported to CNC machining software for manufacturing. They have an in-house design department but after they performed a cost analysis, it was more cost effective for them to outsource this project than take their design team off their current projects to try to meet the scheduling this client required.

SOLUTION

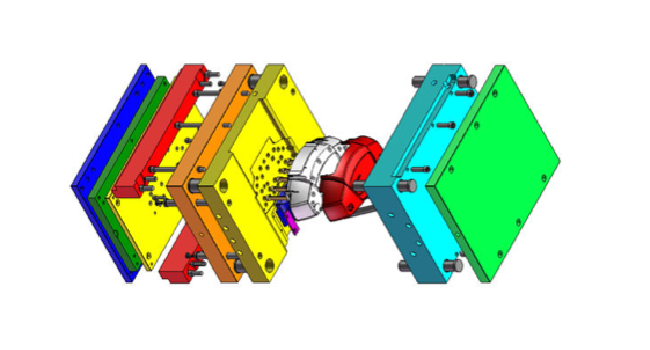

We took our client’s part file, imported to SolidWorks and created a two part mould from it. In order to manufacture certain features on the side of the part, it was necessary to create what is called a side core. This side core slides into place as the mould is closed and the plastic is injected. Once the plastic injection process has completed, the mould opens up, the side core automatically retracts and ejector pins push the finished part from the mould.

By taking on this project, we saved our client the time and the cost of having their internal CAD support staff design the mould. Collaborating with their staff, we came up with a design which far exceeded their customer’s requirements.

SERVICES PROVIDED

- 3D CAD Modeling: Allowed us to identify potential problem areas and improve on the design

- Bill of Material and Cut List: Provided material and material size data for quoting and manufacturing