GOAL

Our client required a system that automated the process of mixing and sifting flour and passing the material through a metal detector before the flour is collected in a tote bag. The second requirement was to have a bypass chute in place to allow flour to skip the sifting and metal detecting processes while a new tote bag was being installed.

SOLUTION

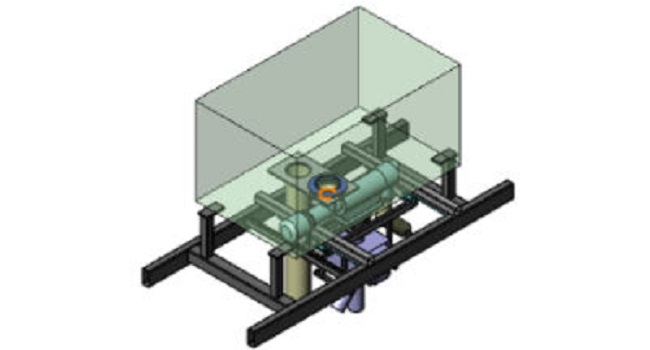

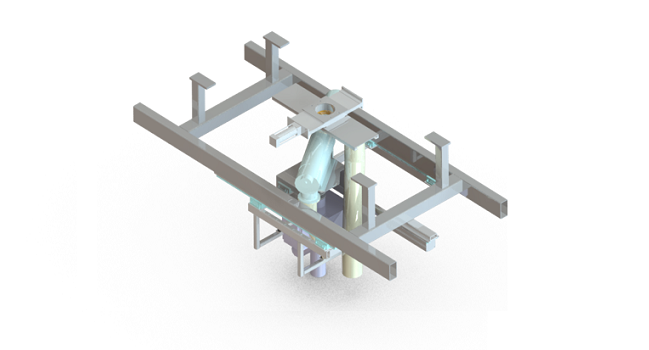

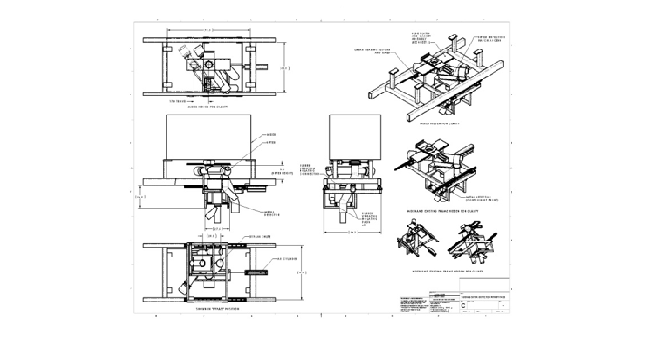

The sifter and metal detector were mounted on a steel tube frame equipped with linear bearing rails. An air cylinder actuated the system by pushing the sifter and metal detector out from underneath the mixer and engaged the bypass chute when a tote bag is being changed out. Once an empty bag is in place, the air cylinder is actuated and normal loading resumes.

SERVICES PROVIDED

- 3D CAD Modeling: Allowed us to identify potential problem areas and improve on the design.

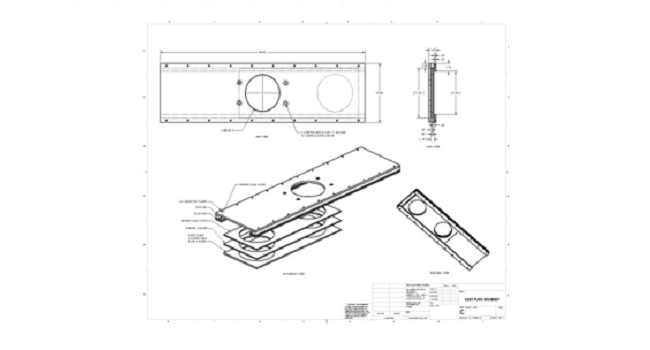

- Bill of Material and Cut List: Provided material type and size data for quoting and manufacturing

- Detailed Manufacturing Drawings: Provided drawings allowing our client to have their product manufactured